-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Installation and placement of high temperature electric furnace:

1. Please choose a well ventilated room, and place the high temperature electric furnace on the surface to prevent hot material from splashing, away from other heat sources.

2. Do not place the high temperature electric furnace on a flammable surface. Do not install the furnace in a place where the heat radiation after opening will cause damage to the high temperature electric furnace.

3. Ensure that there is at least 75 mm of space around the high temperature electric furnace, and it is best to be 1.5 meters above the ground.

4. Do not plug any ventilation holes in the shell or put any objects on the upper surface. In particular, do not block the normal operation of the cooling fan in the shell.

5. If the furnace is used in the process of releasing harmful gases, an appropriate smoke exhaust system should be installed at the same time. Do not connect directly with the furnace chimney.

6. Ensure that the placement of the high temperature electric furnace is conducive to quickly cutting off the power supply.

Instructions for use of high temperature electric furnace:

1. Open the furnace door, check whether there are sundries in the furnace, if there are no sundries, you can start charging the furnace. Pay attention to the amount of charging the furnace can not be too large, and have regular and neat placement.

2. Transport the workpiece to be tested or small batch production to the box type electric furnace.

3. Ensure that there is no problem with the furnace, close the furnace door and lock it tight.

4. Turn on the power supply of the high temperature electric furnace and the controller, and then start setting the temperature and heating rate. 5. After setting the temperature and heating rate, press the start button, the electric furnace begins to heat up.

6. After the experiment is completed, the furnace door can be opened slowly after the temperature drops below 200 degrees, and the experimental workpiece can be taken out quickly.Note: The time to open the furnace door should be as short as possible.

7. If you continue to use the high-temperature electric furnace, repeat the above steps.If you do not use it, close the furnace door and the power supply.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

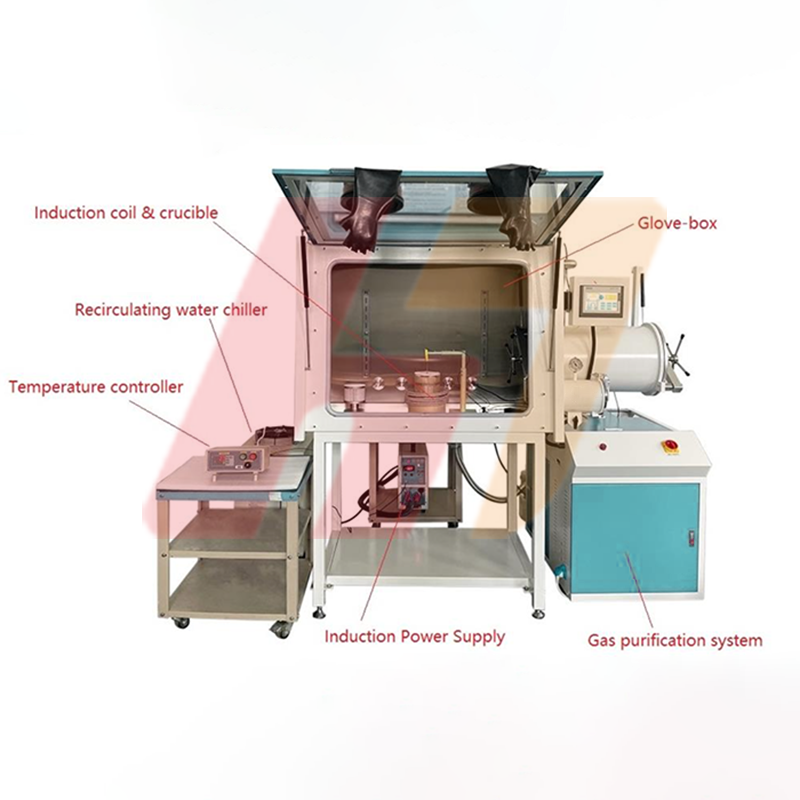

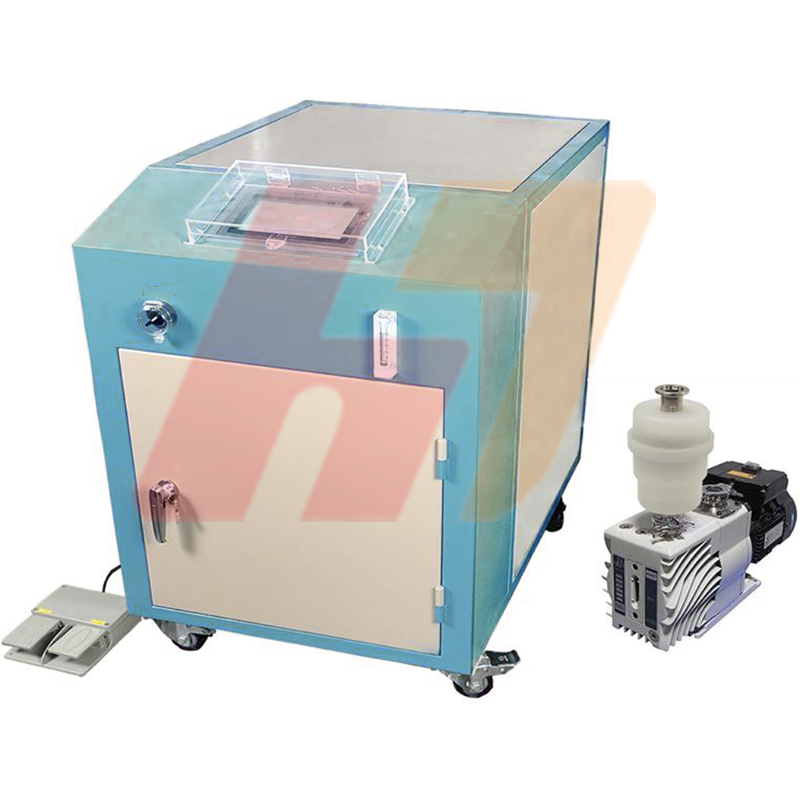

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut