-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

The temperature deviation of 1100 degree high temperature tube furnace refers to the difference between the actual measured temperature and the set target temperature. Temperature deviations can be caused by a variety of factors, including but not limited to the following:

1.Temperature sensor error: The temperature sensor may have a certain measurement error, which may cause the actual temperature and the sensor to read

2.Temperature uniformity in the furnace: The temperature distribution inside the high-temperature tube furnace may not be uniform, and the temperature may be different at different locations.

3.Temperature control system error: the temperature control system of the high-temperature tube furnace may have certain stability and accuracy problems, such as the response time of the temperature controller, the setting of PID parameters, etc., which may lead to the difference between the actual temperature and the set temperature.

4.External environmental effects: external environmental factors, such as room temperature changes, air flow, etc., may have a certain impact on the temperature of the high-temperature tube furnace, resulting in temperature deviation.

To reduce the temperature deviation, the following measures can be taken:

1. Regular calibration: Regularly calibrate the temperature of the high-temperature tube furnace, verify the difference between the actual temperature and the set temperature, and make corresponding adjustments.

1) Preparation: Ensure that the high-temperature tube furnace is stopped and cooled to room temperature. At the same time, prepare the thermometer and calibration equipment required for calibration.

2) Calibration equipment preparation: Select an accurate and reliable thermometer as a calibration reference, preferably using a thermometer that matches the temperature range to be measured in the furnace. Ensure that the accuracy of calibration equipment meets the actual requirements.

3) Selection of temperature calibration points: Select at least two calibration points with known temperatures for calibration. These calibration points should cover the operating temperature range of the furnace, and the temperature values of the calibration points should be able to be accurately measured and verified.

4) Temperature calibration in the furnace: Place the thermometer in the furnace and ensure that it is balanced with the temperature in the furnace. Heat according to the furnace operating manual or manufacturer's instructions to bring the temperature inside the furnace to the temperature of the first calibration point.

5) Temperature calibration: The calibration device reading is compared with the thermometer reading. If there is a deviation, record the deviation value.

6) Adjustment calibration: According to the recorded temperature deviation value, it is necessary to adjust the temperature control system or correction factor of the high-temperature tube furnace, so that the temperature of the furnace is consistent with the reading of the calibration equipment. Depending on the furnace type and temperature control system, it may be necessary to adjust the PID parameters, temperature controller Settings, or other relevant parameters.

7) Repeat calibration: Repeat the above steps, at least at the second calibration point, to verify and fine-tune the calibration results.

8) Record calibration results: record all calibration data, including the temperature value of the calibration point, the calibration equipment reading and the temperature of the high temperature tube furnace after calibration.

2. Temperature balance: To ensure the balanced distribution of the internal temperature of the high-temperature tube furnace, measures such as optimizing the structure of the furnace and increasing insulation materials can be taken to improve the temperature distribution.

3. Optimize the control system: Optimize the temperature control system, including selecting the appropriate temperature controller, adjusting PID parameters, improving the stability of the control system, etc., to improve the accuracy and stability of temperature control.

4. External environment control: minimize the influence of the external environment on the temperature of the high-temperature tube furnace, such as reducing the interference of external air flow on the temperature by means of isolation protection and air duct design.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

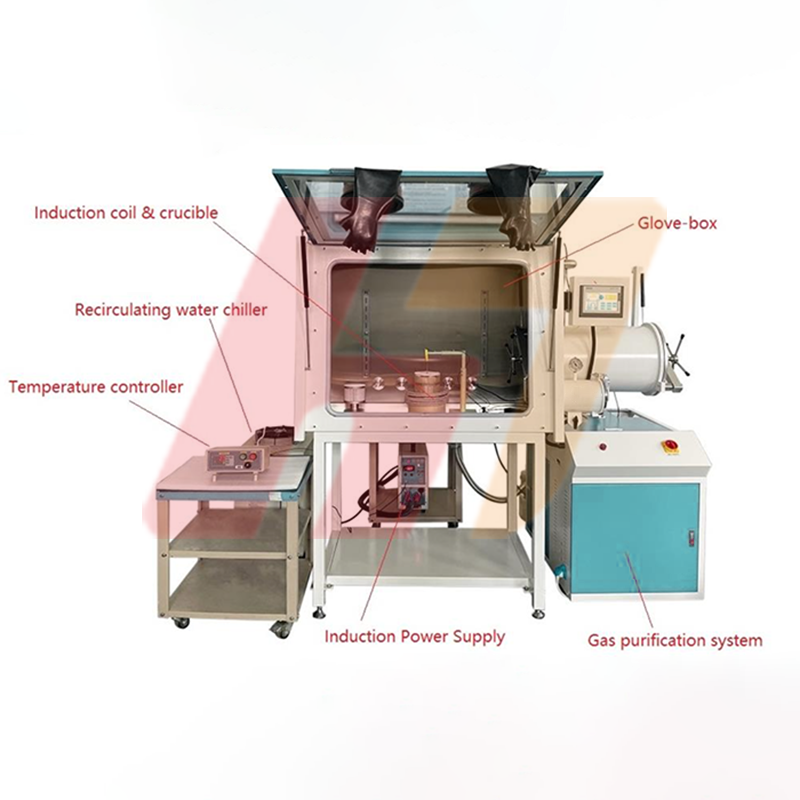

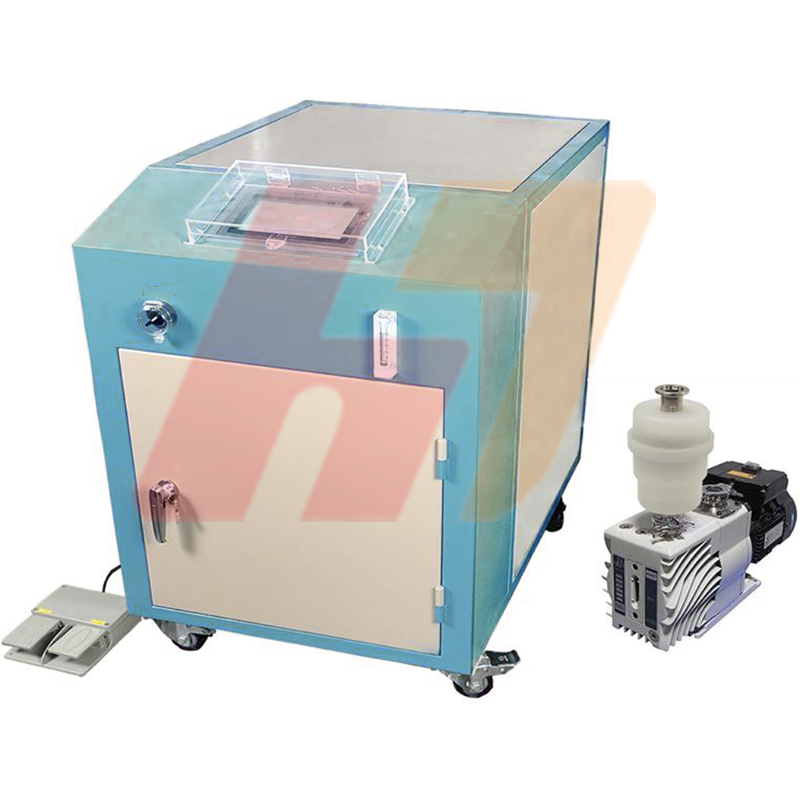

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut