-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

High temperature vacuum tubular furnace is an electronic heating device that exposes materials to different temperatures with precise control and uniformity. It houses a working tube or vessel that processes or heats small samples in an inert atmosphere. This lets you expose materials to a wide range of temperatures in varying periods. The tube furnaces include split tube furnace, horizontal tube furnace, vertical tube furnace, multi zone tube furnace, rotary tube furnace, etc.

The tubular furnace refractory heating coils or ribbons are embedded in the ceramic heating chamber and are responsible for the uniform temperature distribution. HT tube furnace has various applications, including heat treatment, crystal growth, synthesis, and purification of compounds.

Mounted horizontal or vertical design tubular furnaces synthesize and purify inorganic or organic compounds. Operating with minimum produced noise, the tube furnaces are offered in singular and multiple heating zone styles to fit application needs. The tarnish-free stainless steel exterior and high quality insulation ensure equipment longevity. The easily replaceable working tubes provide maximum maintenance flexibility Choose from various maximum temperature, dimensions, tube size, and electrical requirement options.

Tubular furnace is worth having in your lab primarily due to the uniform thermal temperatures of its cylindrical heaters. Multiple sections inside the furnace include several heating elements that evenly distribute heat consistently. The uniform heating of tube furnaces makes them ideal for sensitive thermal processing applications like thermocouple calibration.

On top of this, you can boost its processing capabilities by integrating it with multiple heating zones, allowing you and your staff to fully control temperature gradients. This enables you to finely tune all phases of thermal processing, such as the heating up and cooling down stages.

Also, high temperature vacuum tubular furnace is perfect for processing smaller samples with its smaller volume capacity and quick heat-up rates. This uses up lesser electricity, so you won’t have to worry about wasting energy when powering up the equipment just to test a small batch of sample size, unlike a chamber furnace.

Its sealed work tubes also protect the high temperature vacuum tubular furnace from contaminants and maintain a modified environment for your samples, ensuring testing accuracy.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

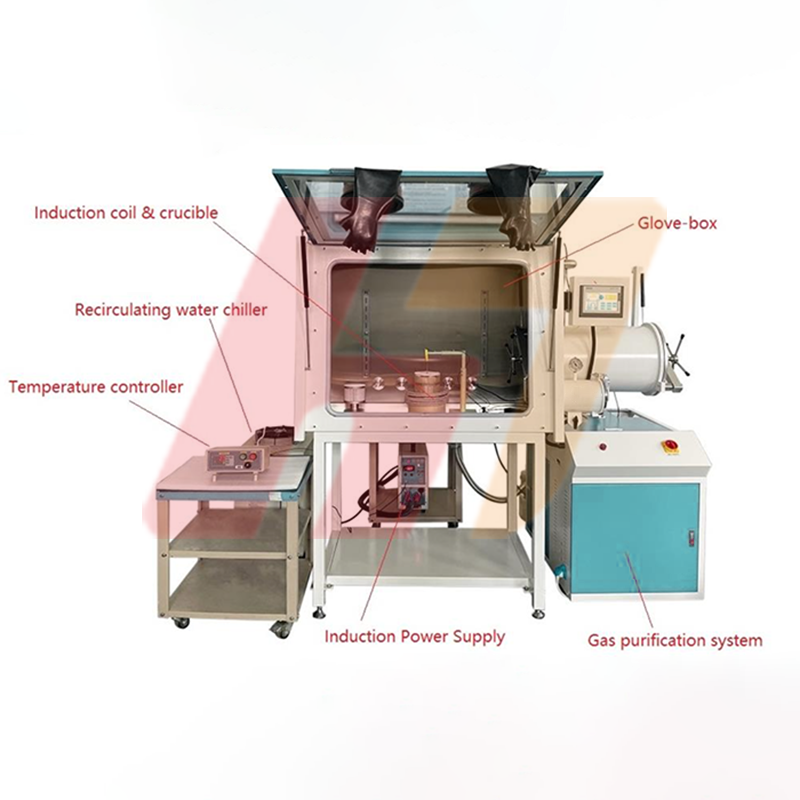

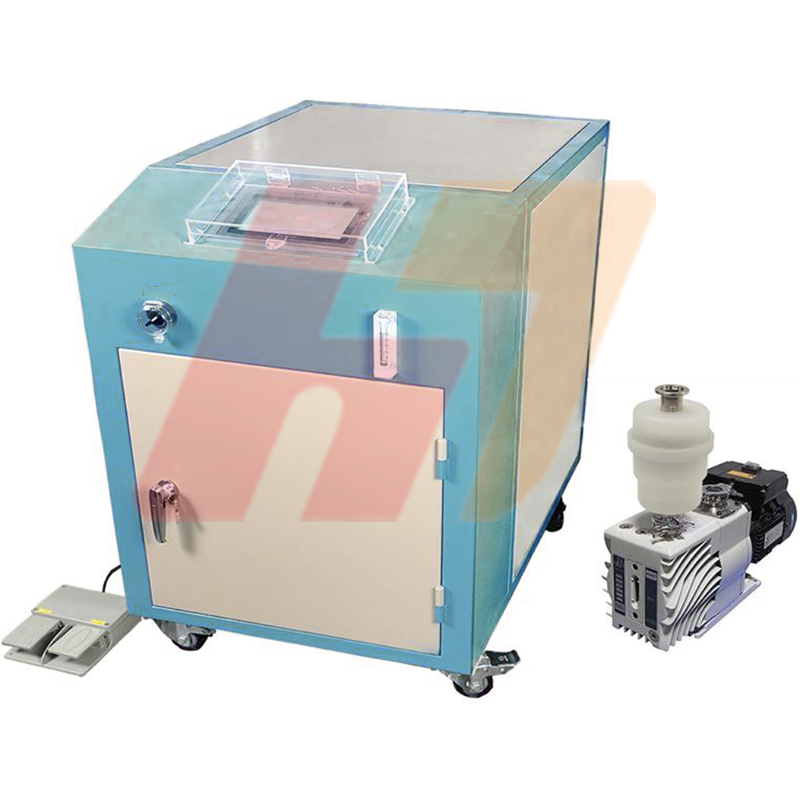

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut