-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

HengTong furnace companies use electromagnetic induction for melting, heating and welding applications across multiple industries. To the typical engineer, induction is a fascinating method of heating. Watching a piece of metal in a coil turn cherry red in a matter of seconds can be surprising to those unfamiliar with induction heating. Induction heating furnace requires an understanding of physics, electromagnetism, power electronics, and process control, but the basic concepts behind induction heating are simple to understand. The principle of induction heating is mainly based on two well-known physical phenomena: Electromagnetic induction, The Joule effect.

Electromagnetic induction

The energy transfer to the object to be heated occurs by means of electromagnetic induction. Any electrically conductive material placed in a variable magnetic field is the site of induced electric currents, called eddy currents, which will eventually lead to joule heating.

JOULE HEATING

Joule heating is the physical effect by which the pass of current through an electrical conductor produces thermal energy. This thermal energy is then evidenced through a rise in the conductor material temperature, thus the term “heating”. One can see Joule heating as a transformation between “electrical engegy” and “thermal energy”, following the energy conservation principal.

Characteristics of Induction Furnace:

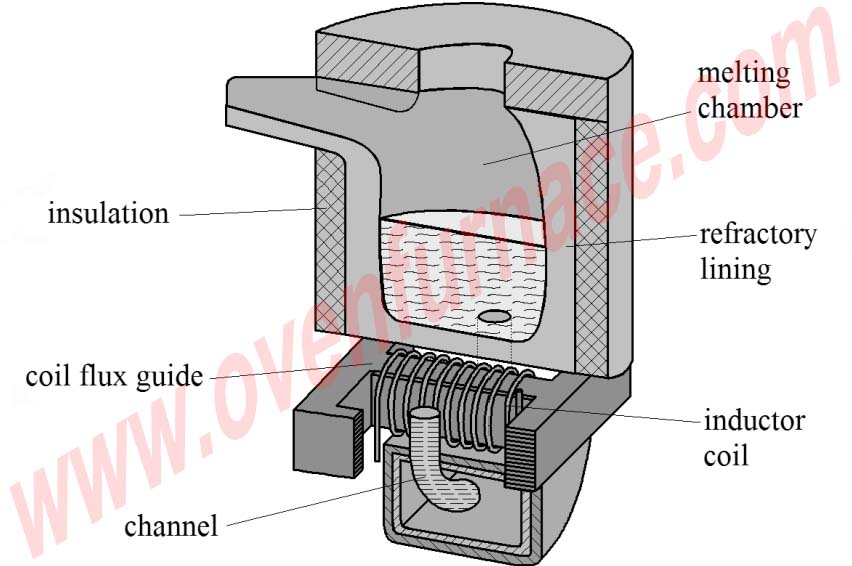

Channel Induction heating Furnace

The channel Induction Furnace consists of a refractory lined steel shell which contains the molten metal. Attached to the steel shell and connected by a throat is an induction unit which forms the melting component of the furnace. The induction unit consists of an iron core in the form of a ring around which a primary induction coil is wound. This assembly forms a simple transformer in which the molten metal loops comprise the secondary component. The heat generated within the loop causes the metal to circulate into the main well of the furnace. The circulation of the molten metal causes a useful stirring action in the melt. The channel Induction Furnace is normally used for melting low melting point alloys, or as a holding and superheating unit for higher melting point alloys such as cast iron.

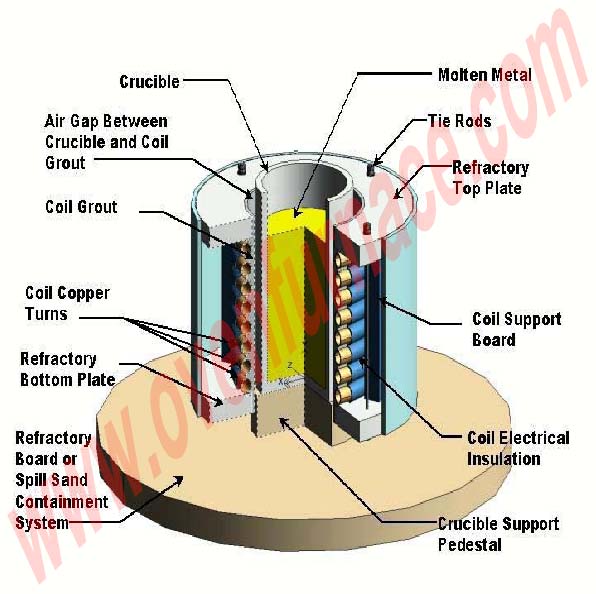

Coreless induction Furnace.

The coreless Induction heating Furnace has a fairly simple construction. It basically consists of a refractory vessel and the surrounding coil borne by a steel frame. When an alternating current (AC) flows through the coil, it creates an electromagnetic field which in turn induces eddy currents in the charged material. This charge material gets heated up as per Joule’s law and with further heat the charge material melts.

The main component of the coreless Induction Furnace consists of a crucible, a power supply unit consisting of transformer, inverter and capacitor bank, the charging arrangement, the cooling system for the power supply and furnace coil, process control system, and the fume extraction equipment.

Discovered by Michael Faraday, Induction starts with a coil of conductive material (for example, copper). As current flows through the coil, a magnetic field in and around the coil is produced. The ability of the magnetic field to do work depends on the coil design as well as the amount of current flowing through the coil.

The basic concepts behind induction heating are simple to understand

The direction of the magnetic field depends on the direction of current flow, so an alternating current through the coil will result in a magnetic field changing in direction at the same rate as the frequency of the alternating current. 60Hz AC current will cause the magnetic field to switch directions 60 times a second. 400kHz AC current will cause the magnetic field to switch 400,000 times a second.

When a conductive material, a work piece, is placed in a changing magnetic field (for example, a field generated with AC), voltage will be induced in the work piece (Faraday’s Law). The induced voltage will result in the flow of electrons: current! The current flowing through the work piece will go in the opposite direction as the current in the coil. This means that we can control the frequency of the current in the work piece by controlling the frequency of the current in the coil.

As current flows through a medium, there will be some resistance to the movement of the electrons. This resistance shows up as heat (The Joule Heating Effect). Materials that are more resistant to the flow of electrons will give off more heat as current flows through them, but it is certainly possible to heat highly conductive materials (for example, copper) using an induced current. This phenomenon is critical for inductive heating.