-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

1. When the Muffle furnace is heated, the furnace jacket will also become hot, and the furnace should be kept away from flammable materials and kept easy to dissipate heat outside the furnace.

2. The working life of the heating element depends on the oxide layer on its surface, the destruction of the oxide layer will shorten the life of the heating element, and each shutdown will damage the oxide layer, so the shutdown should be avoided after the boot.

3. The furnace temperature shall not exceed the maximum temperature when used, so as not to burn the electric heating element, and it is forbidden to pour various liquids and melted metals into the furnace.

4. When doing the ashing test, the sample must be fully carbonized on the electric furnace before being put into the ashing furnace to prevent the accumulation of carbon from damaging the heating element.

5 After several cycles of heating, the insulation material of the furnace may have cracks, which are caused by thermal expansion bow |, and have no effect on the quality of the furnace.

6. Muffle furnace is experimental supplies, shall not be used for other purposes, the sample must be stored with a clean crucible, shall not pollute the furnace.

7. When the resistance furnace is used, it should be taken care of often to prevent accidents caused by self-control failure. When no one is on duty at night, do not use the resistance furnace.

8. After the Muffle furnace is used, the power supply should be cut off to make it cool naturally. The furnace door should not be opened immediately, so as not to crack the furnace suddenly. If necessary, a slit can be opened to speed up the cooling. When the temperature drops below 200°C, the furnace door can be opened.

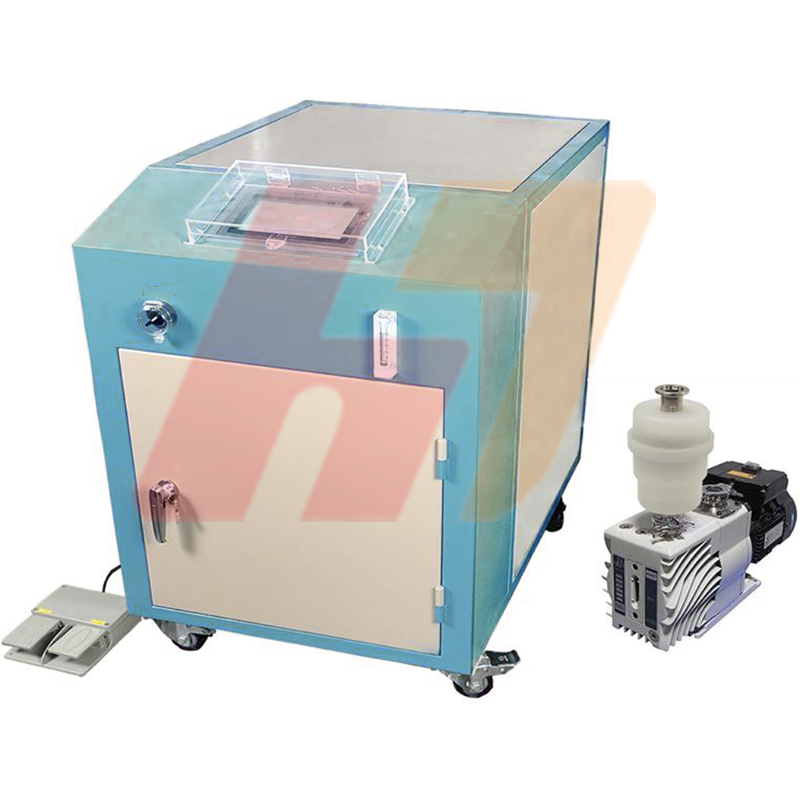

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

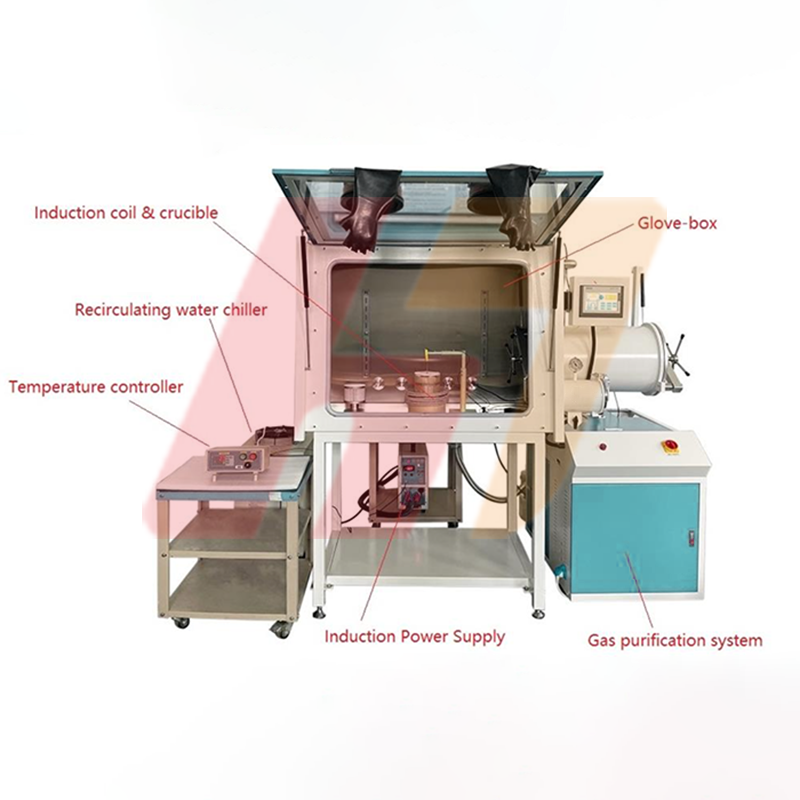

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut