-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

When the heat treatment vacuum furnace is used for processing, the workpiece needs to be cleaned before entering the vacuum furnace, and two situations are prone to occur in this step:

1. The workpiece is not cleaned, and a large amount of anti-rust oil and water remain on the surface.

2, the anti-rust oil on the workpiece is basically cleaned, but there is still a lot of water. After washing directly into the preheating zone, before cleaning ordinary tap water.

In the first case, if there is oil stain on the surface of the workpiece, the appearance of the workpiece is not very good, and the oil stain is sintered on the surface when the workpiece is carburized, which will hinder the infiltration of carbon atoms, and the final is not conducive to cleaning the shot blasting.

The second situation has no effect on the workpiece, and can only increase the burden of the pre-oxidation furnace or preheating zone. It is even better if it can be dried or blow-dried before entering the heat treatment vacuum furnace.

Therefore, in the future, when using heat treatment vacuum furnace for vacuum heat treatment, the workpiece must be cleaned before entering the vacuum furnace, so as not to bring bad effects to the product.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

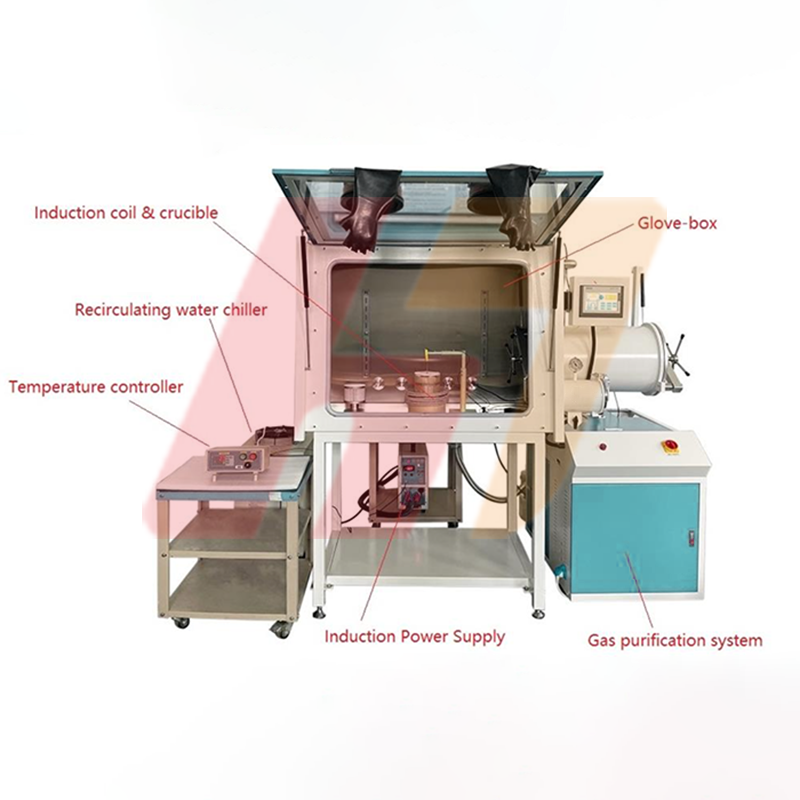

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut