-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Integral heat treatment is a metal heat treatment process that heats the workpiece as a whole and then cools it at an appropriate speed to change its overall mechanical properties. The overall heat treatment of steel is roughly annealing, normalizing, quenching and tempering four basic processes.

Normalizing is the workpiece heated to the appropriate temperature after cooling in the air, the effect of normalizing is similar to annealing, but the obtained organization is finer, often used to improve the cutting performance of the material, and sometimes used for some parts with low requirements as the final heat treatment.

Quenching is the workpiece after heating and holding, in water, oil or other inorganic salts, organic water solution and other quenching media rapid cooling. After quenching, the steel becomes hard, but at the same time brittle. In order to reduce the brittleness of the steel, the quenched steel is insulated for a long time at an appropriate temperature higher than room temperature and lower than 650 ° C, and then cooled, this process is called tempering. Annealing, normalizing, quenching and tempering are the "four fires" in the overall heat treatment, of which quenching and tempering are closely related and often used together.

With the different heating temperature and cooling methods, different heat treatment processes have evolved. In order to obtain a certain strength and toughness, the process of combining quenching and high temperature tempering is called tempering. After some alloys are quenched to form supersaturated solid solutions, they are kept at room temperature or slightly higher at the appropriate temperature for a long time to improve the hardness, strength or electrical magnetism of the alloys. This heat treatment process is called aging treatment.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

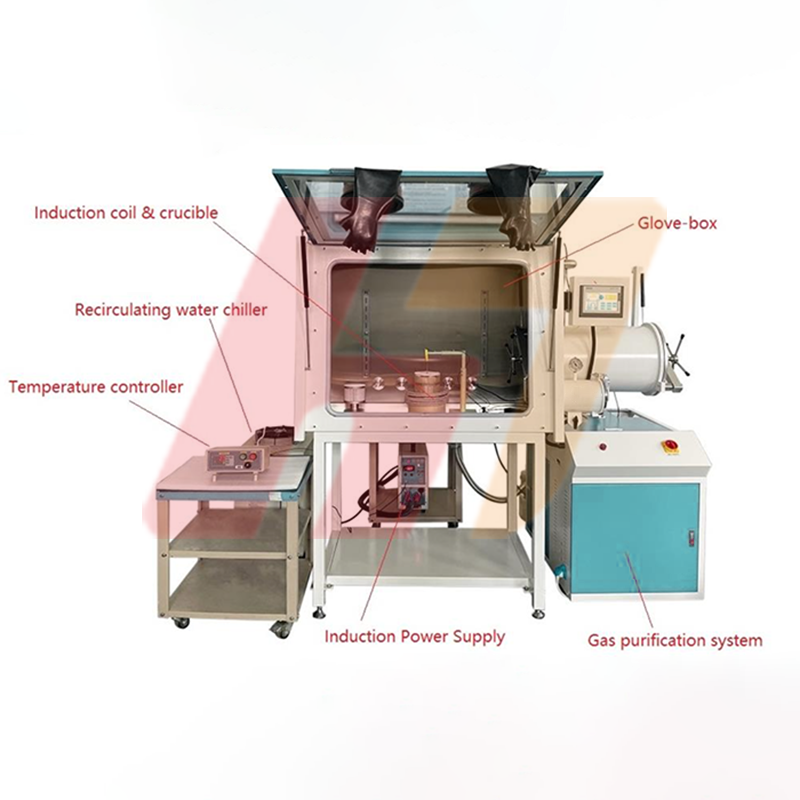

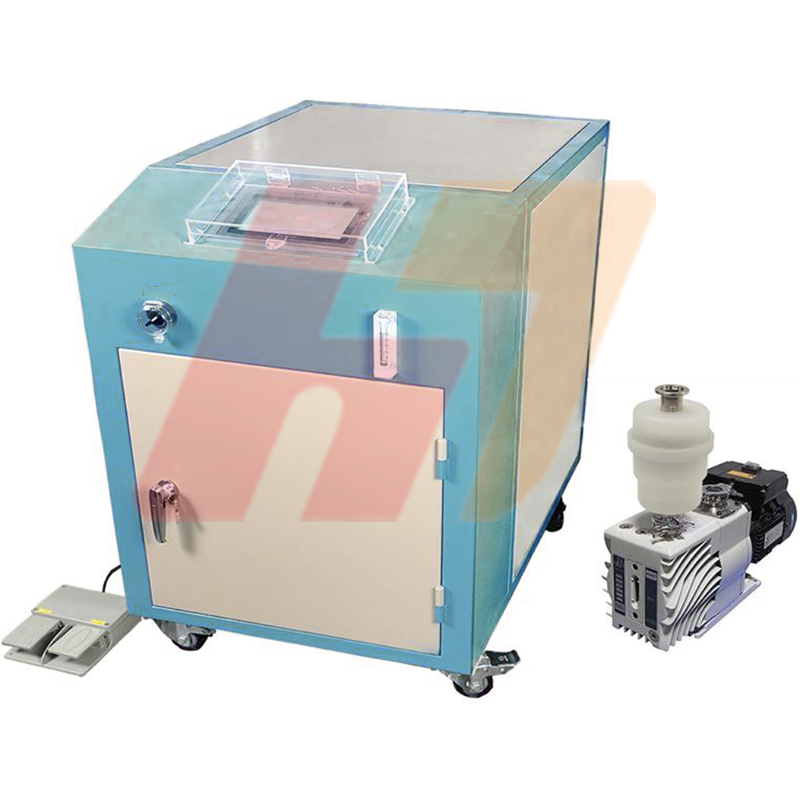

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut