-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

ED SiC heating elements are made from high purity alpha silicon carbide grains. That is extruded in the form of rods or tubes, before being bonded together by a process of re crystallization, at temperatures of over 2500°C. The firing process ensures the creation of rods with strong uniform bonds between adjacent grains, and the particle size distribution is closely controlled to ensure optimum density and resistance to the process atmosphere.

ED SiC heating elements have the conventional central hot zone and two low resistivity cold ends. Elements with unequal cold end lengths can also be supplied if required.

ED SiC heating elements can be supplied in 1 -piece or 3-piece construction, according to the demands of the application. One-piece elements feature a joint free construction, where the cold ends are formed by filling the pore structure with a low resistivity silicon alloy. 3-piece elements feature special low resistance cold ends that are joined to the hot zone using a reliable and strong reaction-bonding technique.

As the resistivity of the hot zone material is consider-ably higher than that of the cold ends, the majority of the heat is generated in the hot zone, when power is applied. The cold ends, which pass through the furnace lining, remain relatively cool, and are sprayed over a short length at the end with aluminum, to form a low resistance contact for the aluminum terminal braids.

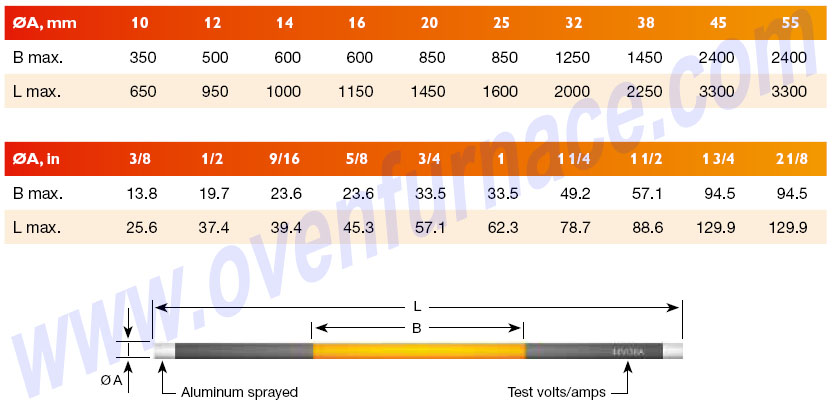

Standard ED SiC heating elements are available in a range of diameters between 10 and 55 mm (3/8 and 21/8 in) as detailed in following drawing. All of the elements are tubular, apart from 10 mm (3/8 in) diameter elements, which are manufactured in the form of solid rods.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

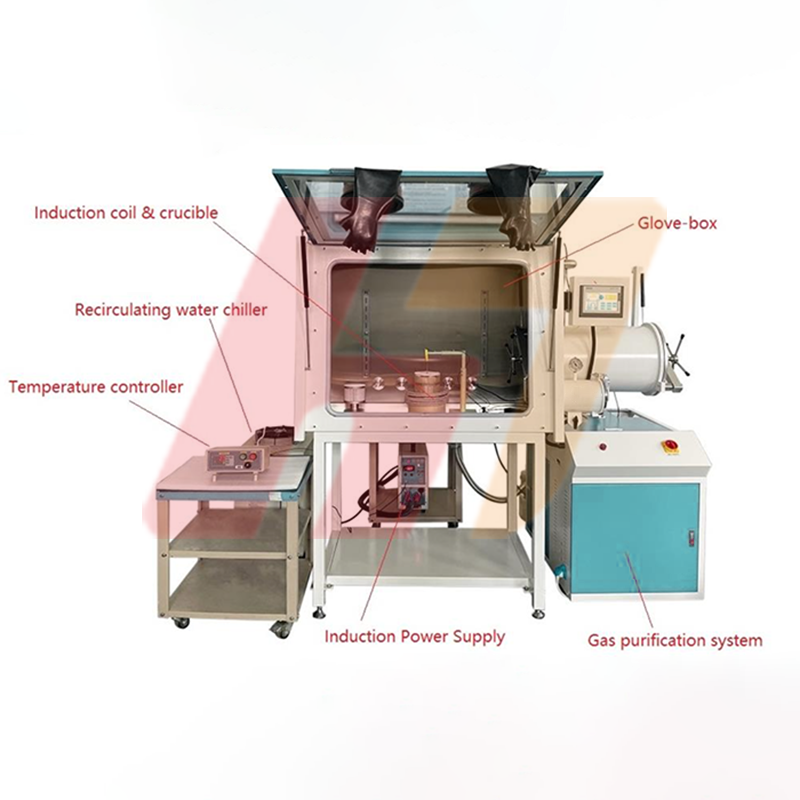

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

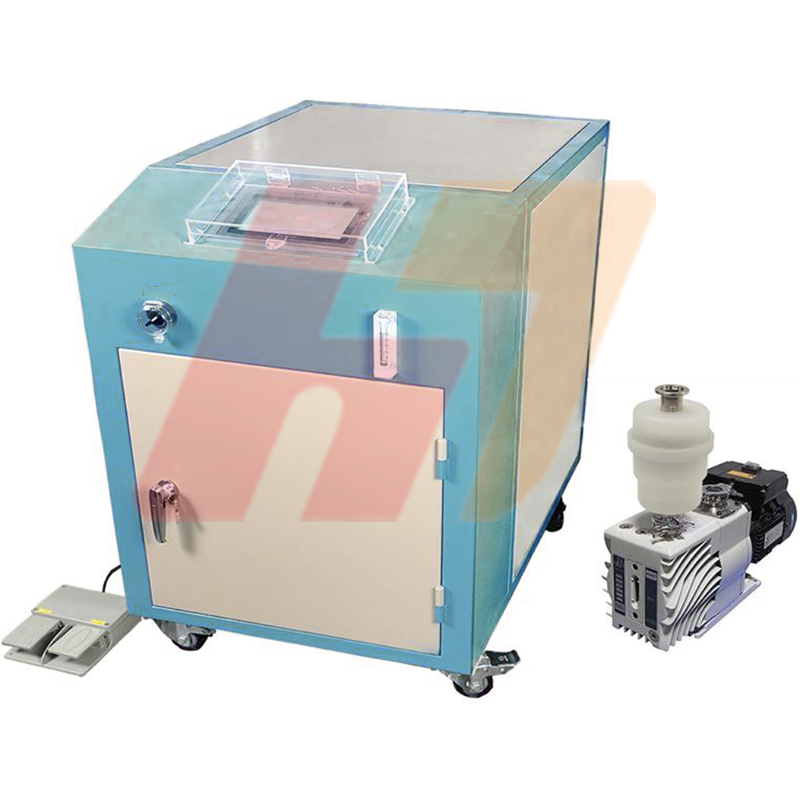

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut