-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

During vacuum sintering in vacuum atmosphere furnace, metal volatilization loss often occurs. Such as the loss of cobalt volatilization when sintered cemented carbide. By strictly controlling the vacuum degree, even if the pressure in the furnace is not lower than the vapor pressure of the sintered metal components, the volatilization loss of the metal can be greatly reduced or avoided. Another problem with vacuum sintering is the decarbonization of carbon-containing materials. This mainly occurs in the heating stage, the oxygen, water in the residual gas in the furnace and the oxide in the powder can react with the combined carbon in the carbide or the free carbon in the material to produce carbon monoxide with the furnace gas extraction. The decarbonization of carbon-containing materials can be solved by increasing the carbon content in the powder and controlling the vacuum degree.

In order to improve the heating speed and the uniformity of the furnace temperature in the vacuum sintering process, an appropriate amount of gas (inert gas or hydrogen) can be passed into the sintering stage. The cooling speed of vacuum sintering can also be improved by the method of circulating gas cooling. In order to prevent the forming agent from contaminating the vacuum device system during sintering, the pressing block should be pre-fired to remove the forming agent before vacuum sintering. In powder metallurgy, vacuum sintering is mainly used for sintering active metals and refractory metals beryllium, thorium, titanium, zirconium, tantalum, niobium, etc. Sintered cemented carbide, magnetic alloy, tool steel and stainless steel; And sintered compounds that react easily with gases such as hydrogen, nitrogen and carbon monoxide.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

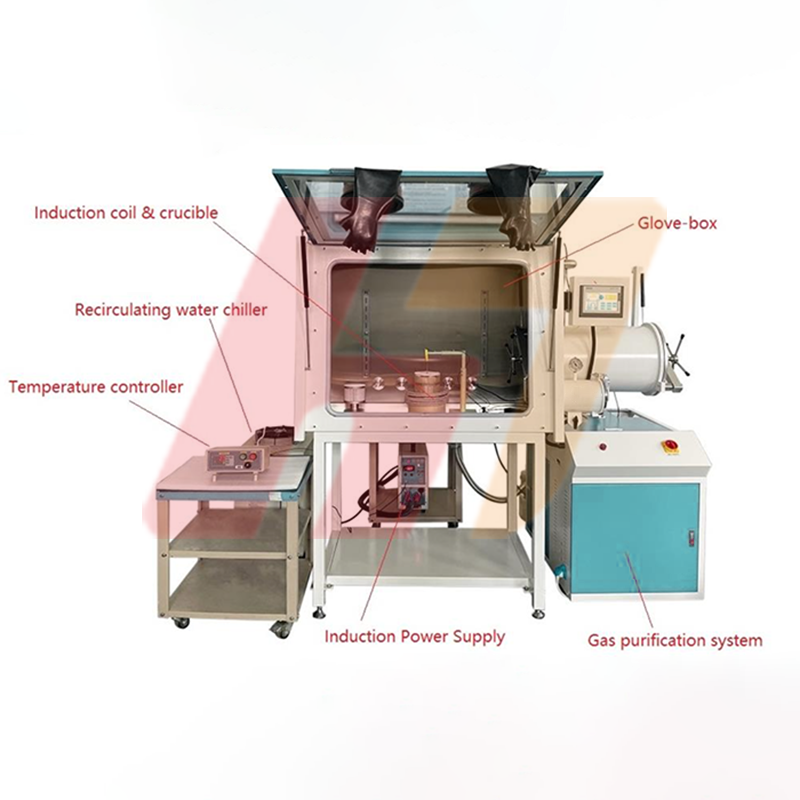

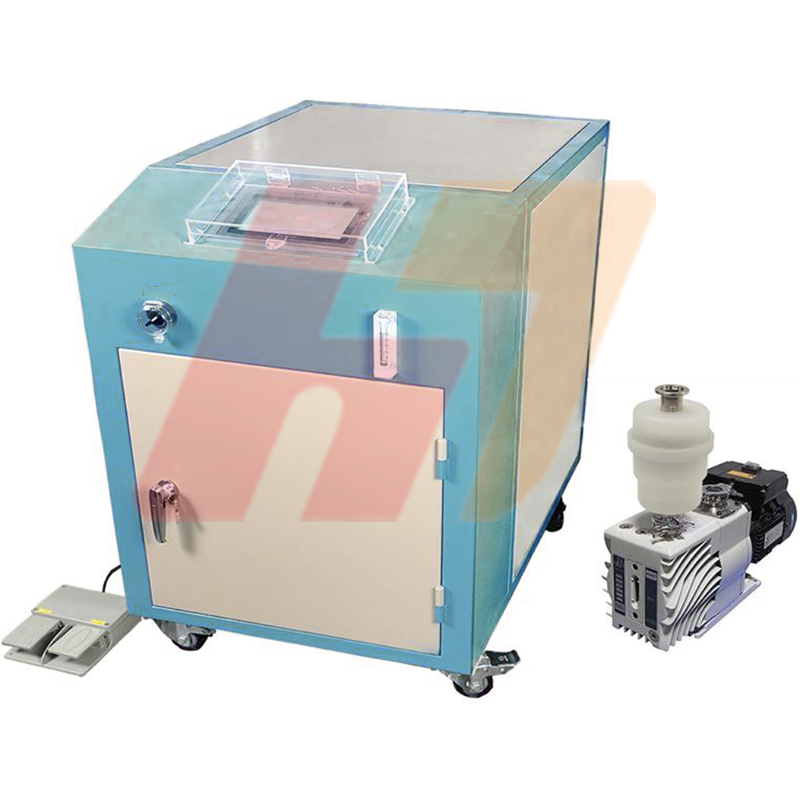

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut