-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Differences Between Rapid Thermal Annealing Furnace (RTP) and Tube Furnace

Rapid Thermal Annealing (RTP) furnaces and tube furnaces are both widely used in materials processing, particularly in semiconductor manufacturing, but they differ significantly in design, operation, and application. Here’s a detailed comparison:

1. Heating Mechanism

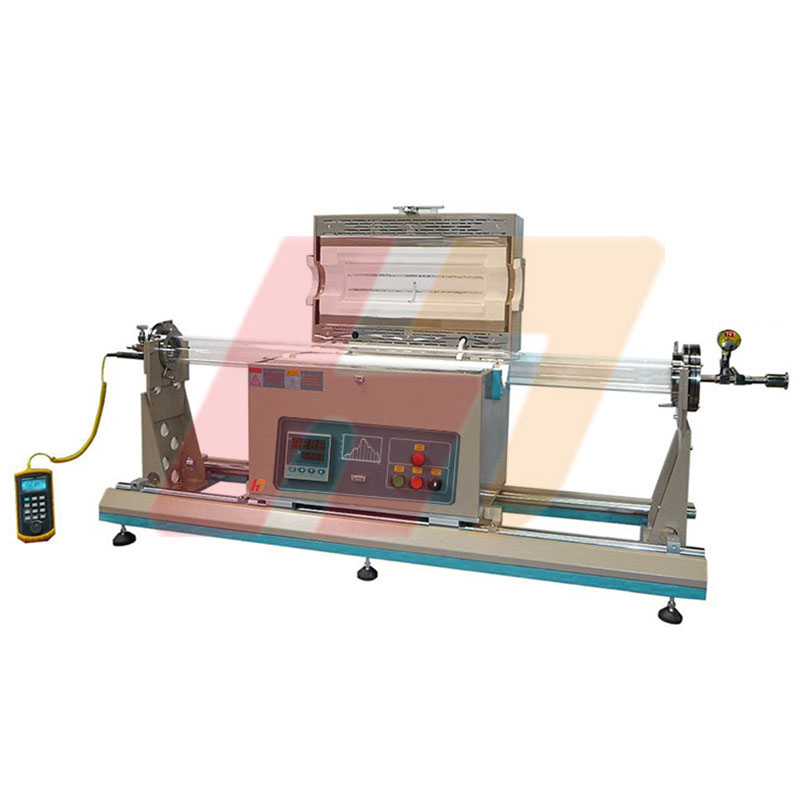

Tube Furnace: Uses resistive heating elements (e.g., nichrome, molybdenum disilicide) wrapped around or embedded in a cylindrical quartz or ceramic tube. Heat is transferred to the sample primarily via convection and radiation, resulting in slower, more uniform heating of the entire chamber.

RTP Furnace: Employs high-intensity heat sources (e.g., halogen lamps, arc lamps) focused directly on the sample. Heat is transferred almost entirely by radiation, enabling extremely rapid heating (up to 100–200°C per second) of the sample, while the surrounding chamber remains relatively cool.

2. Temperature Ramp Rates

Tube Furnace: Slow ramp rates (typically 1–10°C per minute) due to gradual heat diffusion through the chamber. This allows for controlled, steady heating but limits processing speed.

RTP Furnace: Very fast ramp rates (10–200°C per second) because heat is applied directly to the sample. This minimizes thermal exposure time, reducing unwanted diffusion or phase changes in sensitive materials.

3. Temperature Uniformity

Tube Furnace: Excellent uniformity (often ±1°C or better across the entire chamber volume) because the entire furnace reaches thermal equilibrium. Ideal for processing multiple samples simultaneously with consistent results.

RTP Furnace: Uniformity is more challenging due to localized, intense heating. Modern RTP systems use advanced lamp arrays and temperature monitoring (e.g., pyrometers) to achieve uniformity (±2–5°C) across the sample surface, but it is generally less consistent than tube furnaces for large batches.

4. Processing Time

Tube Furnace: Longer processing times (minutes to hours) due to slow heating, soaking, and cooling stages. Suited for processes requiring extended thermal exposure (e.g., annealing thick films, sintering ceramics).

RTP Furnace: Very short processing times (seconds to a few minutes) because of rapid heating and cooling. Used for time-sensitive processes where minimizing thermal budget is critical (e.g., activating dopants in semiconductors without causing excessive diffusion).

5. Atmosphere Control

Tube Furnace: Easily adaptable to various atmospheres (vacuum, inert gases like N₂/Ar, reactive gases like O₂/H₂) via gas inlets/outlets. The sealed tube design ensures stable, uniform gas distribution around all samples.

RTP Furnace: Atmosphere control is possible but more complex. The open or partially enclosed chamber (to allow lamp access) requires efficient gas flow to prevent contamination, and rapid heating can cause gas turbulence, making uniform gas distribution harder to maintain.

6. Sample Size and Throughput

Tube Furnace: Accommodates larger samples or multiple small samples (e.g., wafers, powders, bulk materials) due to the spacious tube. High throughput for batch processing.

RTP Furnace: Typically processes single or a few small samples (e.g., semiconductor wafers up to 300mm) at a time, as rapid heating is less efficient for large or multiple samples. Lower batch throughput but faster per-sample processing.

7. Applications

Tube Furnace:

Annealing thick films or bulk materials.

Sintering ceramics and metals.

Chemical vapor deposition (CVD) or thermal oxidation (with gas control).

Processes requiring long exposure to specific temperatures/atmospheres.

RTP Furnace:

Dopant activation in semiconductors (minimizes diffusion).

Rapid thermal oxidation (RTO) or nitridation of thin films.

Annealing of sensitive materials (e.g., III-V semiconductors, nanostructures) where minimal thermal damage is critical.

High-throughput, single-wafer processing in semiconductor fabrication.

Summary

Tube furnaces excel at slow, uniform, batch processing with flexible atmosphere control, while RTP furnaces are designed for rapid, localized heating to minimize thermal exposure, making them indispensable for high-precision, time-critical applications like semiconductor manufacturing.