-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

Choosing the right type of thermocouple is a matter of matching the thermocouple to your measurement requirement. Here are some areas to take into consideration:

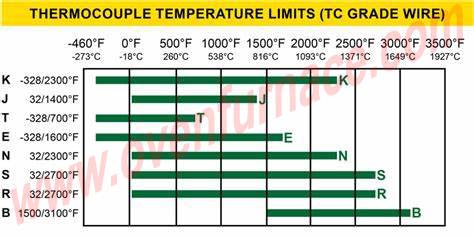

Temperature Range: The different thermocouple types have different temperature ranges. For example, Type T with its Copper leg has a max temperature of 370C or 700F. Type K on the other hand can be used up to 1260C or 2300F.

Conductor Size: The diameter of the thermocouple wires also needs to be taken into consideration when long duration measurements are needed. For example, Type T thermocouples are rated to 370C/700F, however if your thermocouple has #14AWG wires (.064” Diameter) they are rated for 370C/700F. If your thermocouple has #30AWG wires, that drops to 150C/300F. More information can be found here (See the table on the bottom of page H-7).

Accuracy: Type T thermocouples have the tightest accuracy of all the base metal thermocouples at ±1C or ±0.75% whichever is greater. This is followed by Type E (±1.7C or 0.5%) and Types J, K and N (±2.2C or 0.75%) for standard limits of error (per ANSI/ASTM E230).

Other important considerations are the sheath materials (if immersion probe style), insulation material (if wire or surface sensor) and sensor geometry.

The most common types of thermocouples are the Type B, E, J, K, N, R, S, T, C, & P thermocouple. Before choosing the type of thermocouple for your process, make sure you are aware of the limitations of all available calibration types.

Type B Thermocouple

The Type B thermocouple is composed of a platinum-30% rhodium (+) wire versus a platinum-6% (-) wire. This type of thermocouple can be used in oxidizing or inert atmospheres with a service temperature range between 870°C and 1800°C (1000°F to 3600°F). They should never be used in reducing atmospheres.

Vacuum applications are possible for short periods of time. As with all platinum type thermocouples, they should always be protected with a ceramic protection tube. Alumina insulators and protection tubes are preferred to prevent silica contamination from Mullite ceramics.

In most situations, platinum thermocouples should not be placed in any type of metal tube in high-temperature applications Type B thermocouples are less susceptible to grain growth and calibration drifts than R and S type thermocouples.

Type E Thermocouple

The Type E thermocouple is composed of a nickel-10% chromium (+) versus a nickel-45% copper (-) wire. This Type of thermocouple can be used in oxidizing or inert atmospheres with a service temperature range of -200°C to 900°C (330°F to 1600°F).

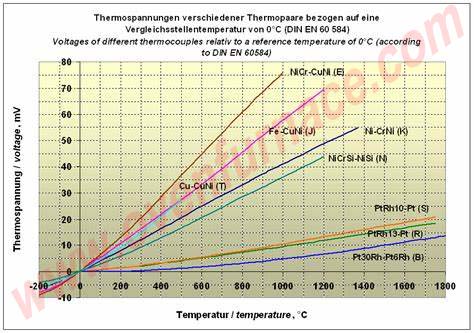

The Type E thermocouple can be used successfully in subzero applications due to high corrosion resistance to high moisture environments. Out of all of the different types of thermocouples, Type E has the highest EMF output per degree.

Type J Thermocouple

The Type J thermocouple is composed of an iron (+) wire versus a nickel-45% copper (-) wire. This type of thermocouple should be used in oxidizing, reducing, vacuum or inert atmospheres with a service temperature range between 0°C and 760°C (32°F to 1400°F).

If the thermocouple is being used over 540°C (1000°F) an 8 gauge wire should be used due to rapid oxidation of the iron (+) wire. Type J thermocouples should not be used in sulfurous applications above 540°C (1000°F).

The negative element, or JN, of a Type J thermocouple can be described by any of the following names Constantan, ThermoKanthal -JNs, HAI-JN1, Cuprona, or, Advances. The positive element, or JP, of a Type J thermocouple can be described by any of the following names: ThermoKanthal-JPs, and lron.

Type K Thermocouple

The Type K thermocouple is composed of a Nickel-10% chromium (+) wire versus a nickel-5% aluminum and silicon (-) wire. This type of thermocouple should only be used in oxidizing or inert atmospheres with a service temperature range between -200°C and 1260°C (-330°F to 2300°F).

They are most widely used at temperatures above 540’C (1000″F) due to superior oxidation resistance in comparison to Types E, T, or J. There are some conditions which should be avoided when using Type K thermocouples. Vacuum applications should not use Type K due to vaporization of chromium in the positive element.

Type K thermocouples should not be used in Sulfurous environments since both elements will rapidly corrode and the negative element will eventually fail mechanically due to becoming brittle.

Reducing atmospheres should also be avoided. Low oxygen levels can cause the Green-Rot phenomenon in which the chromium in the elements starts to oxidize causing large negative drifts in calibration.

Green Rot

Green-Rot is most pronounced when the thermocouples are used between 815°C to 1040°C (1500°F to 1900°F). ln order to avoid this problem, large lD protection tubes should be used to maximize internal air circulation or the installation of an oxygen getter in the bottom of the protection tube.

lf Green-Rot is a serious problem, Type N thermocouples should be installed. The negative element, or KN, of a Type K thermocouple can be described by any of the following names: Alumel2, HAI-KN1, ThermoKanthal-KNs, T-2s, Nickel-silicon, or Nial+.

The positive element, or KP, of a Type K thermocouple can be described by the following names: Chromel2, Tophel+, ThermoKanthal-KPs, Nickel-chrome, T-13, or HAI-KP1.

Type N Thermocouple

The Type N thermocouple is composed of a nickel-14% chromium-1 1/2% silicon (+) wire versus a nickel 4 1/2% silicon-1/10% magnesium (-) wire. The Type N thermocouple is the newest addition to the ISA family. lt was developed to be used under the same conditions as a Type K. Type N should be used in oxidizing or inert atmospheres with a service temperature range between -200°C and 1260°C (-330°F to 2300°F).

The addition of silicon and chromium makes this type of thermocouple more resistant to Green-Rot and less drifting when compared to a Type K. The negative element, or NN, of a Type N thermocouple can be described by any of the following names: Nisil, nickel-silicon, or, HAI-NN1.

The positive element, or NP, of a Type N thermocouple can be described by any of the following names: Nicrosil, nickel-chromium-silicon, or HAI-NP1 .

Type R Thermocouple

The Type R thermocouple is composed of a platinum-13% rhodium (+) wire versus a platinum (-) wire. This type of thermocouple can be used in oxidizing or inert atmospheres with a service temperature range between 0°C and 1480°C (32°F1o 2700°F).

They should never be used in reducing atmospheres. As with all platinum type thermocouples, they should always be protected with a ceramic protection tube. Alumina insulators and protection tubes preferred to prevent silica contamination from Mullite ceramics.

When Type R thermocouples are continuously used at high temperatures, the elements can develop excessive grain growth in time causing mechanical breakage to the thermocouple. In most situations, platinum thermocouples should not be placed in any type of metal tube or in applications where metallic vapors are present.

Type S Thermocouple

The Type S thermocouple is composed of a platinum-10% rhodium (+) wire versus a platinum (-) wire. This type of thermocouple can be used in oxidizing or inert atmospheres with a service temperature range between 0°C and 1480°C (32°F to 2700°F).

They should never be used in reducing atmospheres. As with all platinum type thermocouples, they should always be protected with a ceramic protection tube. Alumina insulators and protection tubes are preferred to prevent silica contamination from Mullite ceramics.

When Type S thermocouples are continuously used at high temperatures, the elements can develop excessive grain growth in time causing mechanical breakage to the thermocouple. In most situations, platinum thermocouples should not be placed in any type of metal tube or applications where metallic vapors are present.

Type T Thermocouple

The Type T thermocouple is composed of a copper (+) wire versus a nickel-45% copper (-) wire. The Type of thermocouple is frequently referred to as copper-constantan.

This type of thermocouple can be used in oxidizing, reducing, or inert atmospheres with a service temperature range between -200°C and 370°C (-330°F to 700°F). The high-temperature use of this thermocouple is also limited due to rapid oxidation of the copper element.

The Type T thermocouple is one of the few thermocouples which have established limits of error for use in subzero and cryogenic applications. This is possible due to the Type T’s superior corrosion resistance in moist environments.

Type C Thermocouple

The Type C or WSR thermocouple is composed of a tungsten-5% rhenium (+) wire versus a tungsten-26% rhenium (-) wire. This Type of thermocouple can be used in high temperature vacuum or inert atmospheres with a service temperature range up to 2316°C (4200°F).

lt has very poor oxidation resistance, which must be taken into consideration. The Type C thermocouple is the most common tungsten-rhenium form of thermocouple due to the conductors being the least brittle at room temperature. This characteristic is very important since brittle conductors create inferior thermocouples.

Type P Thermocouple

The Type P or Platinel 116 thermocouple is composed of a palladium-55%, platinum-31%, and 14% gold (+) wire versus a 65% gold and 35% palladium (-) wire. The Type Thermocouple is a noble-metal form and should be protected in the same manner as a Type R, S, or B.

This type of thermocouple was developed to approximate the Type K curve at high temperatures. Platinel thermocouples can be used in oxidizing or inert atmospheres with a service temperature range up to 1260°C (2300°F). When using Type P thermocouples, Type K extension wire should be used to connect the Type P thermocouple to the instrument.

Note: The thermocouple types we described above are the letter designations assigned by the instrument Society of America (lSA) and adopted as an American Standard in ANSI MC 96.1. The Type C and P letters are exceptions. The Type C and Type P are letter designations commonly used today by thermocouple manufacturers and not the lSA. There are a few other more exotic types of thermocouples, which have been developed, but since they are rarely used we decided not to list them.