-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

The atmosphere furnace can pass hydrogen, argon, nitrogen, oxygen, carbon monoxide and other gases, which is the ideal product for atmosphere protection or atmosphere sintering and atmosphere reduction in colleges and universities, scientific research institutes, industrial and mining enterprises.

Performance characteristics of atmosphere furnace:

1, permeable gas: all inert gases, nitrogen, argon, oxygen, carbon dioxide, water vapor, etc.

2, heating rate: the heating rate is fast, the heating rate is 30℃/ minute, 5℃/ minute is recommended;

3, furnace design: the overall design of the furnace is effective, the furnace does not collapse, heat is not easy to lose, and the service life of the furnace is improved;

4, heating element: resistance wire thermocouple 0-1200℃ (K type), silicon carbon rod 0-1600℃ (s type), silicon molybdenum rod 0-1820℃ (b type);

5, Appearance design: humanized design, beautiful and easy to operate, the outer paint layer is sprayed with high temperature baking process. High temperature, oxidation resistance, acid and alkali resistance. Color selection of aging resistant color, long use time will not fade;

6, temperature control safety: the use of integrated circuit, module control, double circuit protection, so that the electric furnace stable, reliable and safe operation.

Operation and maintenance:

1. Regularly check whether the fastening bolt at the wire joint of the electric heating element is loose, if so, tighten it in time;

2, regularly check whether the radiation heating tube is bent, if it is replaced immediately, to prevent short-circuit accidents caused by bending;

3, regularly check whether there is leakage of the sealing part, if there is timely replacement;

4, regularly check the operation of the fan, if there is abnormal phenomenon, timely maintenance or replacement;

5, regularly check the heating of the electrical components in the control cabinet, and adjust or replace them as required;

6, regularly check the wear and deformation of each bearing part and adjust it.

The atmosphere furnace is based on silicon molybdenum rod as heating element, adopts double shell structure and Japan Shima power 40 segment program temperature control system, phase shift triggering, thyretron control, furnace adopts Japan imported alumina multi-fiber material, double-layer furnace shell is equipped with air cooling system, which can quickly rise and cool down. The shell is sealed as a whole, the cover plate is sealed with extruded high temperature silicone pad, the furnace door is sealed with extruded O-ring and water cooling system, the gas enters and exits through the breeches after passing through the flowmeter, and there are several combustion nozzes at the inlet and outlet of the washing furnace.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

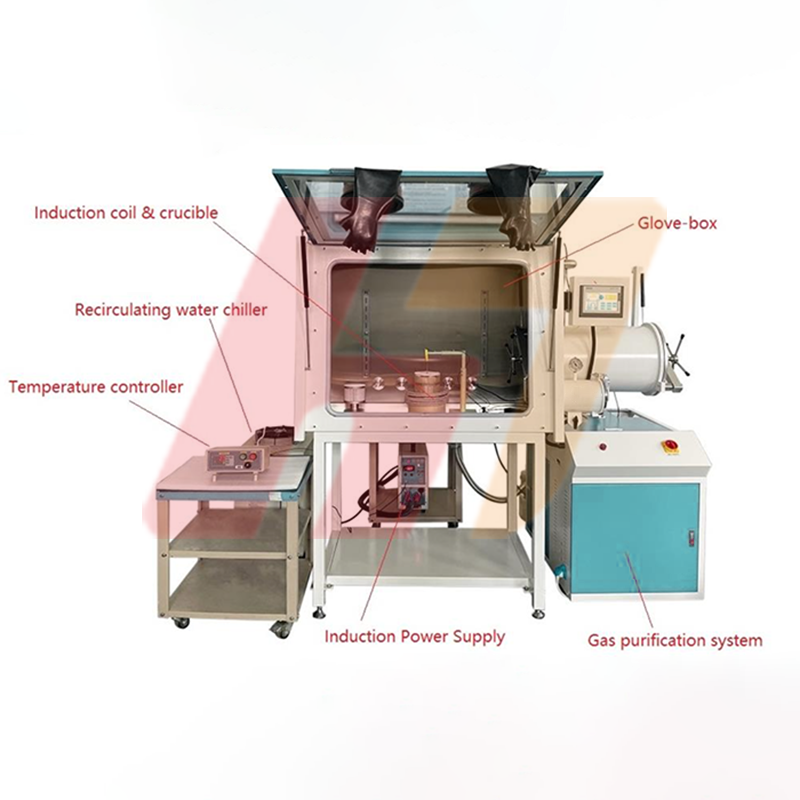

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut