-

Telephone:+0086-371-6376-8262Telephone:+0086-371-6376-8385

-

wechat:abcdefg

-

-

Email:ht@ovenfurnace.com

1, vacuum furnace hydraulic system noise is not normal, oil pump suction pipe or oil filter blocked, clean the oil suction pipe or oil filter.

2, vacuum furnace treatment of titanium alloy, nitrogen should not be used as a cooling gas, because titanium and nitrogen react at high temperatures to form golden titanium nitride.

3, the pressure of the vacuum furnace hydraulic system is unstable, the relief valve is dirty or damaged, clean or repair the relief valve.

4, the hydraulic system pressure is low, the cylinder or the oil motor has a large leak, check the replacement of the cylinder or the oil motor sealing device.

5, the vacuum valve is out of control, the compressed air pressure is not enough, ensure that the compressed air pressure is >0.5MPa.

6, the surface of the oil quenched parts is not bright, the temperature of the parts before oil is too high, the temperature of the parts before oil is not more than 900ºC.

7, the surface of the gas quenching parts is not bright, cooling nitrogen purity is not enough, to ensure that the purity of nitrogen (volume fraction) is above 99.99%.

8, the oil pump does not discharge oil, the rotation direction of the pump shaft is wrong, change the power connector of the oil pump motor.

9, the cylinder or the oil motor rotation is shaking, there is air in the system, the air in the system is removed.

10, working vacuum quenching, should use vacuum quenching oil, the oil has a low saturated vapor pressure.

11. The active connection part of the vacuum furnace is all sealed with O-type rubber ring, and this part is cooled by water.

12, the maintenance of the vacuum furnace should be in a vacuum or filled with pure nitrogen, to avoid suction and moisture absorption when usually not used.

13, vacuum heating radiation mainly, the workpiece in the furnace should be maintained spacing.

14, during the heating process, the workpiece and the material in the furnace will be deflated, so that the vacuum degree will be reduced.

15, vacuum tempering furnace should have a fast cooling device. The pressure of cooling water should be greater than 0.2Mpa, and the flow rate is adjustable.

16, heating: After putting the workpiece, generally pre-pumped to 6.6Pa before heating.

New Sapphire Vacuum Crystal Growth Furnace Bolsters Scientific Research and Industry Development

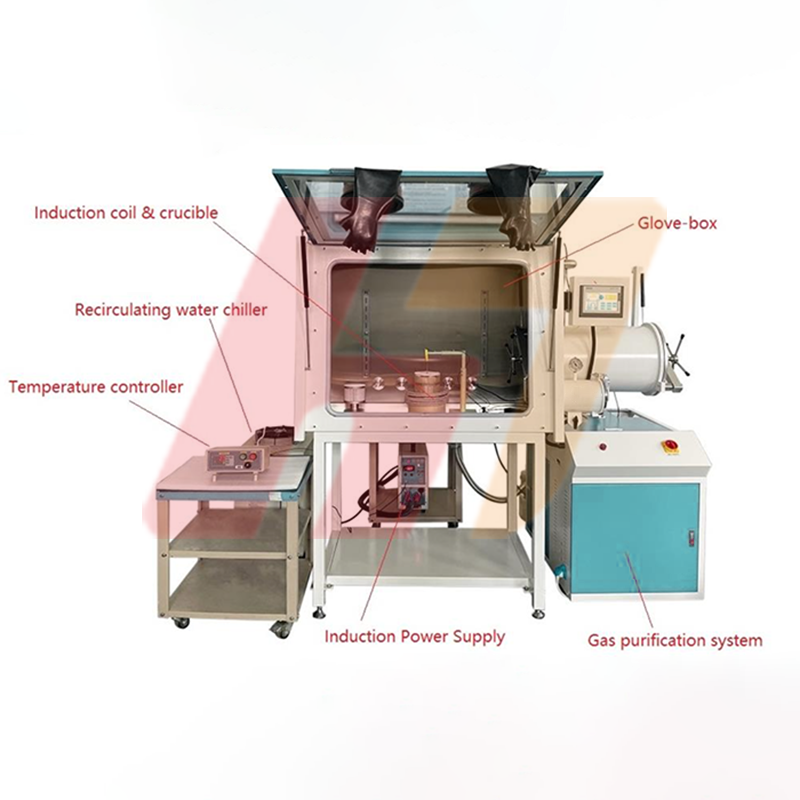

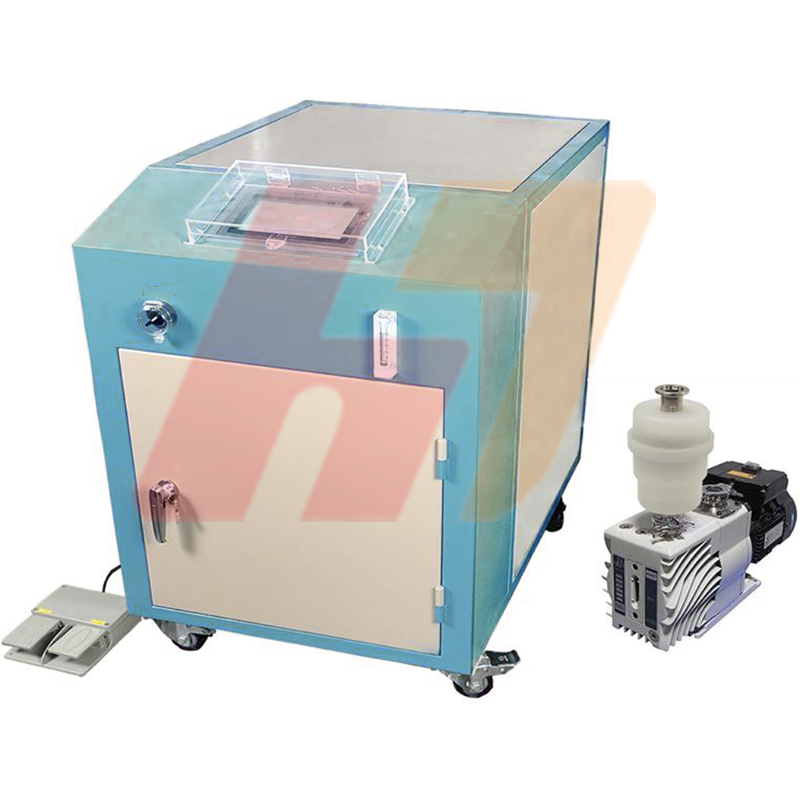

Innovative glove box induction melting system with gas purification function (1ppm) to assist high-purity production

Product: Automatic Recirculating Gas Purification System (O2 < 1 ppm) With Temperature Control System

Innovative technology leads to creating ultra pure environment - Automatic Recirculating Gas Purification System (O2 & H2O < 1 ppm) For Glovebox makes a stunning debut